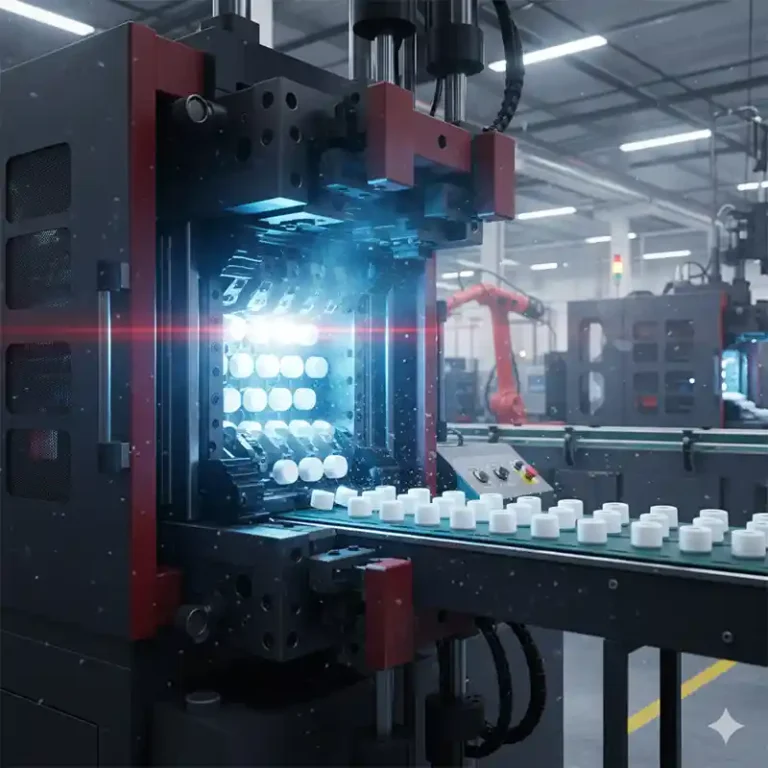

PE Blow Molding Machines

Plastic Caps in Miami: Wholesale Supply & Custom Manufacturing for Your Business

The Closure Rate: Why Your Plastic Caps in Miami Strategy Defines Product Success and Profitability

In Florida’s fast-paced market, where logistics and product presentation are as crucial as the formulation itself, your container’s closure is the final touchpoint with the consumer. This small component—the plastic cap—carries a disproportionate load of responsibility: it must seal freshness, guarantee safety, and reflect your brand’s quality. If you are seeking a reliable and strategic supply of Plastic Caps in Miami, you face a decision that goes beyond unit pricing.

The key question we will address is: In a volatile supply chain environment, how can you secure high-quality, customized, and cost-effective plastic caps without compromising your profit margins? In this detailed article, we break down the closure supply strategy within the Miami region. We will show you why the dual capability of your supplier (distribution and manufacturing) is your competitive edge, offering unique insights to optimize your logistics and closure design. By the end, you will have the tools to secure your product integrity and maximize profitability.

PE Blow Molding Machines

The Closure Dynamic: Why Miami is Key to Your Cap Supply Chain

Miami, as the Gateway to the Americas and a central distribution hub, imposes unique demands on packaging supply. The plastic cap must not only function flawlessly on the filling line but also withstand the rigors of export to tropical climates and intensive logistical handling.

PE Blow Molding Machines

Advantages of a Local Supply of Plastic Caps in Miami

Choosing a local Miami-based supplier offers tangible benefits that directly impact your operational cost and market responsiveness:

Drastic Reduction in Lead Times: By bypassing customs delays and transoceanic freight, a local provider ensures your Plastic Caps in Miami arrive at your facility faster, enabling true Just-in-Time production.

Quality Control and Communication: The ability to visit your supplier’s distribution center or manufacturing plant improves communication and reduces errors related to stock or specification mismatches.

Mitigation of Supply Chain Risks: Over the past five years, reliance on overseas sourcing has proven fragile. A local partner in Florida shields your production from global shocks.

Key Data Point: It is estimated that lead times for custom closures can be reduced by up to 60% when manufactured or stored within the U.S. compared to direct international import.

PE Blow Molding Machines

Closure Types: Tailoring the Plastic Cap to Your Product

Choosing the right closure type is your product’s first line of defense. In the manufacturing of Plastic Caps in Miami, two key materials dominate: HDPE (High-Density Polyethylene) and PP (Polypropylene), due to their low cost and chemical resistance.

In-Depth Analysis of Closure Standards

Screw Caps (Continuous Thread – CT): The gold standard for reliability and ease of use. It is the most common option for food, supplements, and pharmaceutical products. The key lies in thread precision to guarantee an airtight seal.

Snap-On Closures: Used where quick access is required, such as in the cosmetics market or certain industrial containers. The engineering complexity of this cap requires more precise mold maintenance.

Flip-Top and Dispensing Closures: Essential for products requiring controlled dosing (soaps, sauces). The complexity of this two-piece cap increases the manufacturing cost and requires more sophisticated mold maintenance.

Practical Example 1: The Heat Sealing Challenge A Florida juice bottling company needs caps that withstand a hot-fill process without deformation. A supplier with manufacturing expertise (like AMK) can recommend PP caps with a specific gasket design, outperforming generic distributors who only offer standard HDPE.

PE Blow Molding Machines

The Strategic Leap: Buying Caps vs. Manufacturing Your Own Supply

This is where AMK Plastics’ dual capability offers unique insights. The decision between buying caps from a supplier and manufacturing them internally defines your company’s control and margin.

When Demand Outpaces Wholesale Purchasing

For a business handling volumes exceeding 5 million units annually of Plastic Caps in Miami, the wholesale purchasing model becomes a constraint:

Variable vs. Fixed Cost: Wholesale purchasing is a perpetual variable cost. Internal manufacturing, via a Cap Injection Molding Machine, converts the cap cost into a fixed cost of machine depreciation and raw materials (the lowest possible cost).

Exclusive Customization: Only in-house manufacturing allows you to have a truly unique cap design (ej., with an engraved logo) that acts as a patentable brand asset.

Total Quality Control: If a filling line stops due to faulty caps, having total control over the injection molding machine allows for immediate correction of the mold or the process parameters.

Practical Tip 2: The Mold ROI Analysis Calculate the Return on Investment (ROI) for an injection mold. If your volume of Plastic Caps in Miami is high, the initial investment in a high-cavity mold is often amortized within 12-18 months. After that point, the cost per cap reduces to almost the cost of the raw material alone, multiplying your margin.

Dual Positioning: AMK Plastics, The Supplier That Closes the Supply Loop

Our authority in Plastic Caps in Miami stems from a deep understanding of both sides of the market: we know the pressures of buying because we are distributors, and we know the solution to those pressures because we are machinery experts.

Local Cap Inventory Meets Manufacturing Expertise

We not only stock a robust inventory of standard closures for quick delivery across the Miami area, but that same expertise in the final product informs our machinery recommendations. When advising on the purchase of a Cap Injection Molding Machine, we do so from the perspective of:

The precise Tonnage required for your cap size.

The need for a Multi-Cavity Mold to achieve necessary volume.

The specific Resin Type (HDPE vs. PP) that best suits your final product.

Practical Example 3: Avoiding the Wrong Machine Purchase A common mistake is buying an oversized injection machine to save on cycle times. An expert supplier like AMK Plastics, which understands closures, will recommend the most energy-efficient machine for high-speed cap production, saving on energy costs and factory floor space in Florida.

The plastic cap is not a mere accessory; it is a strategic decision. For businesses in Florida, the key to maximizing profit margin and supply reliability lies in partnering with an entity that understands both sides of the equation: the immediacy of wholesale purchase of Plastic Caps in Miami and the long-term profitability of in-house manufacturing. AMK Plastics offers the dual solution: fast supply today and the best injection molding machinery for your total control tomorrow.

Stop Managing Scarcity. Start Managing Production.

Are you ready to secure your plastic closure supply chain?

Contact us today to:

Request a Wholesale Quote for your immediate supply of Plastic Caps in Miami.

Request an ROI Analysis to determine if a Cap Injection Molding Machine is the next strategic move for your company.

blow molding machines for business, blow molding investment, blow molding advantages, plastics industry growth, plastics manufacturing profitability, blow molding machine distributor, plastics machinery supplier