PE Blow Molding Machines

Unbeatable Benefits of Producing Containers with PE Blow Molding in Florida

In the highly competitive landscape of American manufacturing, particularly within the strategic hub of Florida, the choice of production technology is far more than a technical decision—it’s a direct determinant of long-term profitability and market positioning. If your business relies on manufacturing hollow containers, bottles, or drums, one technology stands out as the gold standard for efficiency, cost-effectiveness, and versatility: Polyethylene (PE) Blow Molding.

But why is this technology so critical, and more specifically, why is the implementation of cutting-edge PE Blow Molding Machines the perfect strategic move for the fast-paced Florida market? In this detailed guide, we will break down the tangible benefits and distinct competitive edge this technique offers, shifting your packaging production from a necessary expense to a powerful engine for strategic growth. By the time you finish reading, you will have a clear roadmap for optimizing your processes and cementing your brand’s authority in the region.

PE Blow Molding Machines

The Geographic and Economic Edge: Why PE Blow Molding Thrives in Florida

Florida, with its unique climate, bustling tourism, and critical position as a logistical gateway to Latin America and the Caribbean, presents distinct opportunities and challenges for the plastics industry. PE Blow Molding Machines are uniquely suited to capitalize on this geography, offering an ideal combination of production efficiency, product durability, and market responsiveness.

PE Blow Molding Machines

PE's Resilience and Versatility Against Florida's Climate Demands

Polyethylene is the preferred material in blow molding for a fundamental reason: its resilience. In a state prone to high temperatures and intense humidity, PE delivers:

Superior Durability: Containers manufactured with PE better withstand temperature fluctuations and humidity exposure without cracking or degrading. This is crucial for products stored in hot warehouses or shipped across varied climates.

Low Raw Material Cost: High-Density Polyethylene (HDPE) is one of the most affordable and easiest resins to process, directly leading to reduced production costs—a vital factor for maintaining competitive margins in the American market.

Safety and Compliance: PE is widely recognized and certified for contact with food and beverages, immediately opening your production to Florida’s highly lucrative agricultural, juice, and bottled water markets, all while ensuring regulatory compliance.

Key Data Point: According to industry studies, raw material costs typically account for approximately 60–80% of a container’s total cost. Implementing the process through PE Blow Molding Machines provides aggressive optimization of this ratio.

PE Blow Molding Machines

Production Efficiency That Turns Costs into Revenue

The true power of blow molding lies in its operational efficiency. Modern PE Blow Molding Machines don’t just produce items; they automate profitability.

Rapid, Continuous Production Cycles

Unlike some other molding methods that require multiple cooling or assembly steps, PE blow molding is a highly integrated, single-step process:

Minimized Waste and Scrappage: The process generates minimal material waste (known as “flash”), which can often be reprocessed immediately within the machine itself. This dramatically reduces raw material loss and minimizes waste disposal costs.

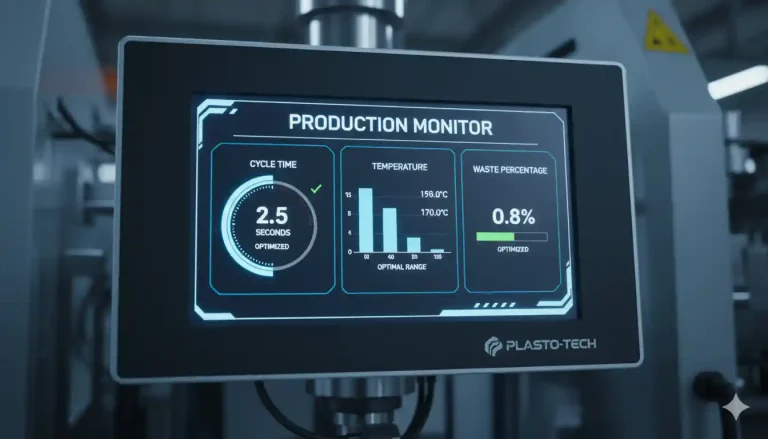

Advanced Automation and Precision: State-of-the-art machinery, like that distributed by AMK LLC Plastics, is equipped with PLCs (Programmable Logic Controllers) that ensure millimetric process control. This precision drastically lowers human error and allows the machinery to operate 24/7 with minimal supervision—essential for fulfilling large national packaging contracts.

Consistent Wall Thickness (Light-Weighting): Advanced extrusion blow molding allows for superior control over the container’s wall thickness. This not only guarantees the structural integrity of the final product but also enables manufacturers to slightly reduce material usage without compromising quality (known as light-weighting), leading to significant scale savings.

PE Blow Molding Machines

PE Blow Molding Machines

The Competitive Advantage of Design and Adaptability in the US Market

The American consumer market is driven by product differentiation and convenience. PE Blow Molding Machines provide the design flexibility necessary to make your products stand out on crowded retail shelves.

Flexibility in Shape and Size Design

Blow molding is uniquely suited for creating containers with complex geometries, integrated handles, narrow necks (for bottles), or wide openings (for jugs and drums).

Practical Example 1: The Consumer Products Market: A national consumer goods company operating in the Miami area can design a visually unique, ergonomic bottle with an integrated handle. This is achieved in a single PE blow molding step, eliminating the cost and complexity of separate handle assembly.

Practical Example 2: Chemical & Industrial: Manufacturers of automotive fluids or industrial chemicals can leverage PE blow molding to produce extremely durable, thick-walled drums and containers that meet stringent DOT regulations, while still being cost-effective for mass production.

Adaptability to the Region's Logistic Demands

Located in a key logistics hub like Miami, American businesses require machinery that can rapidly adapt to domestic and international shipping demands.

Quick Mold Changeover: Modern PE Blow Molding Machines are engineered for efficient mold changes. This capability allows you to rapidly pivot production between a 5-gallon container and a 250ml bottle in a matter of hours, minimizing machine downtime and maximizing your responsiveness to urgent or seasonal national orders.

Inventory Reduction (Just-in-Time): The high production speed allows Florida-based companies to operate with a leaner, Just-in-Time inventory model. This reduces high warehousing costs and mitigates the risk of product obsolescence, especially valuable in industries with quick turnaround requirements.

Conceptual Case Study: The Success of the National Beverage Bottle A major beverage co-packer serving the Southeast implemented a high-output extrusion blow molding machine. Previously, they faced long lead times from third-party bottle suppliers. By internalizing production with PE blow molding, they not only slashed the per-unit cost by 22% but also gained the ability to rapidly produce new promotional bottle shapes, giving them a critical edge in meeting retailer demands.

Sustainability and the Future: Positioning Your Brand in America’s Circular Economy

The demand for sustainability from both regulators and consumers is escalating across the US. Polyethylene blow molding is a critical technology for participating in the circular economy.

Superior Processing of Recycled Materials

PE is one of the easiest and most widely recycled plastics, and the latest generation of PE Blow Molding Machines is specifically designed to handle high percentages of Post-Consumer Recycled Material (PCR-PE) or internal reprocessed materials.

Regulatory Compliance: As states across the US (and potentially Florida) increase mandates on the recycled content in packaging, owning machinery that can efficiently process recycled feedstock is both a competitive advantage and a path to effortless compliance.

Marketing and Brand Story: Utilizing PE blow molding machines to manufacture containers with recycled content allows American businesses to powerfully communicate a strong sustainability narrative to their B2B clients and end consumers, which is increasingly essential for winning major contracts.

Polyethylene blow molding is far more than just a technique; it is a strategic capital investment. In the demanding and competitive US market, particularly with the logistical intensity of the Florida hub, where production efficiency, design versatility, and cost optimization are paramount, PE Blow Molding Machines represent the technology that balances high output with maximum profitability.

By adopting this technology, your company not only drives down packaging costs (through material savings and automation) but also gains the invaluable flexibility to quickly respond to the evolving demands of the American and export markets.

The Time to Act Is Now.

To transform your container production and secure maximum efficiency in Florida, you need a partner that not only distributes the machinery but also deeply understands your market dynamics.

Stop Outsourcing Your Growth Potential.

If you are ready to optimize your packaging solutions Florida, minimize your operational costs, and gain a decisive competitive edge with industry-leading PE blow molding technology, AMK PLASTICS is your strategic partner.

Contact our industrial blow molding machinery experts today for a personalized consultation. We will analyze your specific production needs and recommend the ideal PE Blow Molding Machine that will maximize your efficiency and profitability in the American market.

Start Your Journey to Smarter, More Sustainable Production!

blow molding machines for business, blow molding investment, blow molding advantages, plastics industry growth, plastics manufacturing profitability, blow molding machine distributor, plastics machinery supplier